Centralized oil equipment refers to an integrated system designed to efficiently manage the extraction, transportation, and processing of oil within a single, coordinated framework. Typically utilized in large-scale oil production facilities, this equipment encompasses a broad range of machinery and technology, including drilling rigs, compressors, pipelines, storage tanks, and processing units. By centralizing these components, companies can optimize operational efficiency, streamline maintenance, reduce transportation costs, and minimize environmental impact, all while maintaining stringent safety standards. Additionally, centralized control systems and monitoring tools play a crucial role in maximizing production efficiency and ensuring real-time responses to any potential issues or anomalies.

The implementation of centralized oil equipment is particularly advantageous in managing the complexities of modern oil production, where remote locations and challenging environments require highly coordinated logistical strategies. The integration of advanced technologies such as automation, data analytics, and machine learning further enhances the effectiveness of these centralized systems. For instance, predictive maintenance tools can anticipate equipment failures before they occur, reducing downtime and operational costs. Moreover, centralized systems often incorporate robust cybersecurity measures to protect sensitive data and critical infrastructure from potential cyber threats. Overall, the centralized approach not only meets the demands of modern oil production but also supports sustainability goals by improving resource management and minimizing environmental footprints.

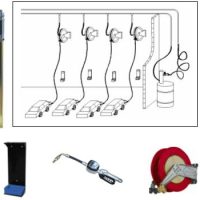

Centralized Oil Equipment

Centralized Oil Equipment